What Are The Steps To Binding A Book?

What Are The Steps To Binding A Book?

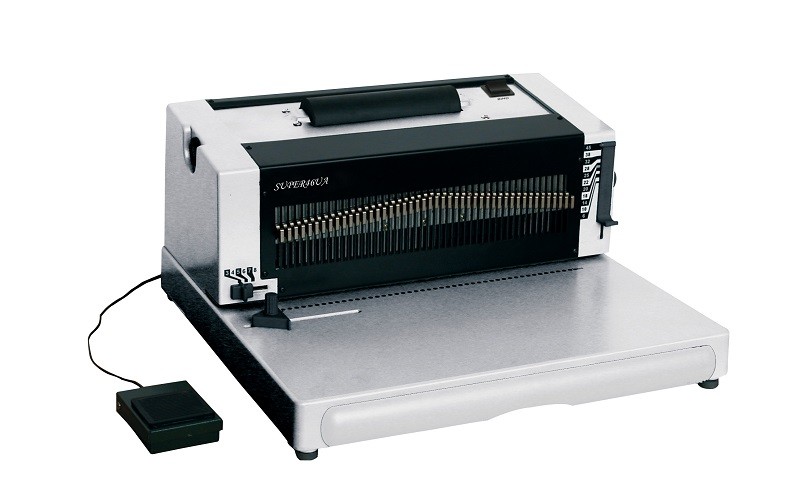

Whatever business you’re in, a professionally bound document can make a fantastic impression that puts you ahead of your competition – and binding them onsite can drastically cut your expenses. Whether you’re using a spiral punch machine from the new Rhin-O-Tuff Onyx series or another type of wire binding equipment, here are the basic binding steps that will yield great results every time.

1. Determine The Binding Type

There are different types of binding elements including

Plastic Coil

Double Loop Wire

Once you decide which of these you want for your particular document, you can then set up the appropriate hole-punch pattern and style that works best with your chosen binding.

The pattern is the number of holes per inch.

The style is the shape of the hole: round, rectangular, square or oval.

2. Choose Your Punch Pattern

Choose an effective punch pattern based on the number of pages in your completed document. A thick document, i.e. one with many pieces of paper, needs more space between holes in order to insert your binding element without missing holes or damaging the element.

Generally, the thicker the document, the fewer holes per inch are required. For example, it’s easier to bind a 50 page document using a 4:1 punch pattern (4 holes per inch) than a 5:1 pattern of 5 holes for every inch.

3. Install The Die, Punch The Holes and Assemble

Install the die with the appropriate pattern and style into your Rhin-O-Tuff spiral punch machine, punch the holes, and assemble the document with your chosen cover. The last step is to bind it all together.

4. Insert the Binding

Different types of bindings create documents with a unique, professional appearance, and each binding element is threaded through the holes in a specific way.

Double Loop Wire – Line up and thread the wire through the holes using your wire binding equipment.

Plastic Coil – Insert the coil into the first hole and use an electric coil inserter to thread it through the rest of the holes.

Comb – Use a plastic comb opener to thread the comb binding into your holes. Once it’s properly situated, close the comb to complete the binding.

With the right equipment and this easy process, your organization can have professionally punched and bound documents made on site for a fraction of the cost of outsourcing the job to a printing company.

Just tell me what you want, a customized product is welcome!

- Name:

- Lois

- Tel:

+86-571-88963506

- Email:

- marketing@hzsuper.com

- Skype:

- supubinding

- Address:

- Jingda Road,Shanlian Development Zone,Sandun,Hangzhou,China,310030